ADDITIVE MANUFACTURING is the magazine devoted to industrial applications of 3D printing and digital layering technology. We cover the promise and the challenges of this technology for making functional tooling and end-use production parts.

Issue link: https://am.epubxp.com/i/1019177

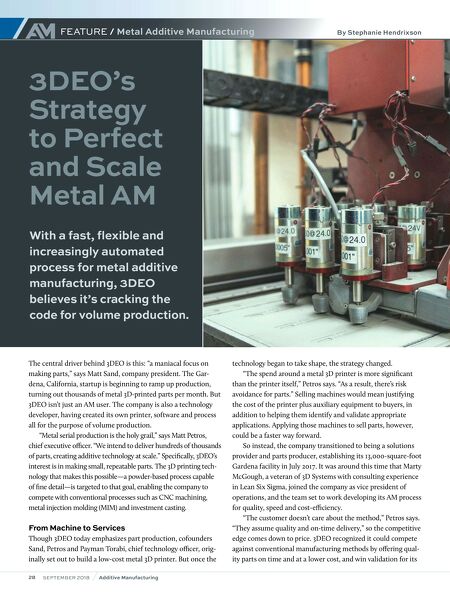

SEPTEMBER 2018 Additive Manufacturing FEATURE / Metal Additive Manufacturing 28 By Stephanie Hendrixson 3DEO's Strategy to Perfect and Scale Metal AM With a fast, flexible and increasingly automated process for metal additive manufacturing, 3DEO believes it's cracking the code for volume production. The central driver behind 3DEO is this: "a maniacal focus on making parts," says Matt Sand, company president. The Gar- dena, California, startup is beginning to ramp up production, turning out thousands of metal 3D-printed parts per month. But 3DEO isn't just an AM user. The company is also a technology developer, having created its own printer, software and process all for the purpose of volume production. "Metal serial production is the holy grail," says Matt Petros, chief executive officer. "We intend to deliver hundreds of thousands of parts, creating additive technology at scale." Specifically, 3DEO's interest is in making small, repeatable parts. The 3D printing tech- nology that makes this possible—a powder-based process capable of fine detail—is targeted to that goal, enabling the company to compete with conventional processes such as CNC machining, metal injection molding (MIM) and investment casting. From Machine to Services Though 3DEO today emphasizes part production, cofounders Sand, Petros and Payman Torabi, chief technology officer, orig- inally set out to build a low-cost metal 3D printer. But once the technology began to take shape, the strategy changed. "The spend around a metal 3D printer is more significant than the printer itself," Petros says. "As a result, there's risk avoidance for parts." Selling machines would mean justifying the cost of the printer plus auxiliary equipment to buyers, in addition to helping them identify and validate appropriate applications. Applying those machines to sell parts, however, could be a faster way forward. So instead, the company transitioned to being a solutions provider and parts producer, establishing its 13,000-square-foot Gardena facility in July 2017. It was around this time that Marty McGough, a veteran of 3D Systems with consulting experience in Lean Six Sigma, joined the company as vice president of operations, and the team set to work developing its AM process for quality, speed and cost-efficiency. "The customer doesn't care about the method," Petros says. "They assume quality and on-time delivery," so the competitive edge comes down to price. 3DEO recognized it could compete against conventional manufacturing methods by offering qual- ity parts on time and at a lower cost, and win validation for its